Artificial Intelligence (AI) is no longer a distant futuristic concept; it has become a driving force in many sectors, especially within industrial automation. The ability of AI to learn, adapt, and make decisions in real-time has made it a powerful tool for industries looking to increase efficiency, reduce costs, and optimize their production processes. As AI continues to evolve, its integration into industrial systems is revolutionizing how we think about manufacturing, logistics, and supply chains.

The Rise of Industrial Automation with AI

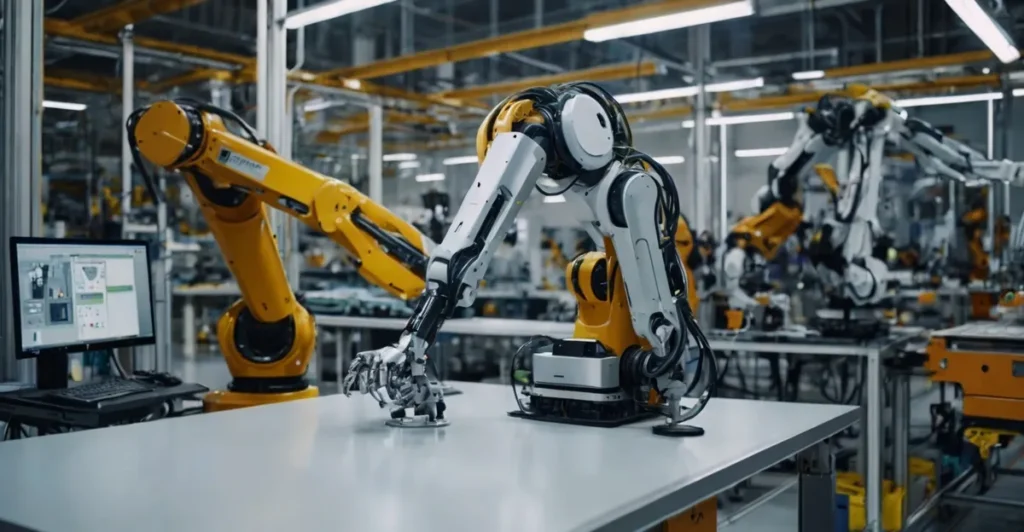

Industrial automation is not a new concept; it’s been around since the early 20th century with the advent of mechanisation and robotics. However, AI has taken this automation to new heights by incorporating intelligent decision-making into machines and systems. Traditional automation relied on pre-programmed rules, but AI allows machines to analyse data, learn from patterns, and make decisions independently without constant human oversight.

Industries such as automotive, electronics, and pharmaceuticals have been among the earliest adopters of AI-powered automation. For instance, automotive manufacturers use AI to streamline the assembly process, ensuring precision and efficiency at every stage. In electronics manufacturing, AI systems monitor quality control by identifying defects more accurately than human inspectors ever could.

One of the most significant developments in this area is predictive maintenance. By leveraging AI algorithms, machines can predict when they are likely to fail, allowing for maintenance to be carried out before a breakdown occurs. This not only minimises downtime but also extends the life of the equipment, leading to substantial cost savings for companies.

Key Technologies Driving AI-Powered Industrial Automation

Several core technologies are pushing the boundaries of what AI can achieve in industrial automation:

1. Machine Learning (ML): Machine learning is at the heart of AI automation. By training algorithms on vast amounts of data, machines can learn to perform tasks that were previously thought to be too complex. For example, ML algorithms can identify patterns in production data, enabling more efficient operations and faster decision-making.

2. Robotics and AI Integration: Robots have long been used in manufacturing to handle repetitive tasks. However, AI enables these robots to go beyond mere repetition. AI-driven robots can now adapt to different tasks, detect environmental changes, and collaborate with human workers in a way that wasn’t possible before. Cobots, or collaborative robots, are a prime example, where AI allows robots to work alongside humans safely in factories.

3. Internet of Things (IoT): IoT is a network of connected devices that collect and share data. When combined with AI, IoT becomes even more powerful. For example, in a factory setting, sensors on machinery can collect real-time data about temperature, speed, and performance. AI systems then analyse this data to optimise operations or flag potential issues before they escalate into serious problems.

4. Computer Vision: AI-driven computer vision systems are being used extensively in industries that require high levels of accuracy and precision. These systems allow machines to “see” and make real-time decisions based on visual inputs. In industries like electronics or pharmaceuticals, computer vision ensures quality control by detecting even the slightest defects or irregularities on production lines.

5. Natural Language Processing (NLP): Although more commonly associated with customer service or marketing applications, NLP is also making its way into industrial automation. By enabling machines to understand and respond to verbal commands, NLP facilitates smoother interactions between human operators and AI-powered systems.

Benefits of AI Automation for Industries

The integration of AI in industrial automation brings several significant benefits, helping businesses to become more competitive in an increasingly tech-driven economy.

1. Increased Efficiency: AI can analyse data and optimise processes faster and more accurately than humans. This leads to more streamlined operations, reducing production times and improving overall efficiency. For example, in manufacturing, AI can ensure machines work at peak performance by adjusting their speed or calibrating them to match the production requirements.

2. Cost Reduction: One of the primary advantages of AI automation is the potential for cost savings. AI systems help businesses lower operational costs by reducing human error, preventing costly machine breakdowns, and improving resource management. Predictive maintenance alone can save companies millions by avoiding unexpected machinery failures and minimising repair costs.

3. Improved Quality Control: AI-powered systems can monitor production lines with a level of precision that humans can’t match. By using advanced sensors and machine learning, these systems can detect defects early in the production process, ensuring that only high-quality products reach the market.

4. Safety and Risk Mitigation: In hazardous industrial environments, AI-driven robots and systems can perform dangerous tasks, reducing the risk of injury to human workers. For example, AI-powered machines are used in industries like mining or chemical processing, where they can carry out tasks that would be too risky for humans.

5. Flexibility and Adaptability: Unlike traditional automation systems that are rigid and limited to predefined tasks, AI-powered systems can adapt to new situations. This flexibility allows companies to respond more quickly to changes in demand or supply chain disruptions, making them more resilient in an ever-changing market.

Challenges of Implementing AI in Industrial Automation

While the benefits are numerous, the road to AI-driven industrial automation isn’t without its challenges.

1. High Initial Costs: Implementing AI technologies can be expensive, particularly for smaller businesses. The costs involved in upgrading existing machinery, integrating AI systems, and training staff can be a significant barrier to adoption.

2. Data Privacy and Security Concerns: As AI systems rely heavily on data to function, concerns about data privacy and security become paramount. Industries must ensure that the vast amounts of data collected by AI systems are stored securely and used responsibly.

3. Workforce Impact: There is ongoing debate about the impact of AI automation on jobs. While AI can increase productivity and create new job roles focused on managing and maintaining AI systems, it can also lead to job displacement in certain sectors, particularly those involving manual or repetitive tasks.

4. Technological Complexity: Implementing AI in industrial settings requires specialised knowledge and expertise. Many businesses may lack the technical skills needed to develop, deploy, and maintain AI systems, leading to a reliance on third-party providers.

5. Ethical Considerations: As AI takes on more decision-making roles in industrial processes, questions about ethics arise. How do we ensure AI makes fair and unbiased decisions? How do we maintain accountability when machines, rather than humans, are driving critical processes?

Future Outlook: AI’s Role in Revolutionizing Industry

The future of AI automation looks promising, with industries across the board embracing new technologies that push the boundaries of what’s possible. As AI continues to evolve, it will further streamline industrial processes, drive innovation, and reduce costs. In the coming years, we can expect to see more widespread adoption of AI in areas like supply chain management, autonomous manufacturing, and even AI-powered decision-making at the executive level.

Moreover, industries will increasingly combine AI with other emerging technologies like blockchain, augmented reality (AR), and quantum computing to create even more sophisticated systems. AI won’t just be about automating tasks; it will fundamentally change how businesses operate, enabling more intelligent decision-making and greater adaptability in the face of global challenges.

For industries willing to embrace the challenges and invest in the technology, AI automation offers the potential to drive significant growth and innovation. While hurdles remain, the rewards are undoubtedly worth it, positioning businesses to thrive in the increasingly AI-driven future of industry.

Conclusion

AI automation is transforming industries at an unprecedented pace, reshaping how we approach manufacturing, logistics, and production. With the power to enhance efficiency, reduce costs, and improve safety, AI is driving a new wave of industrial revolution. However, implementing AI is not without its challenges, from high costs to ethical concerns. Businesses that strategically adopt AI-powered automation, though, stand to gain a competitive edge in a rapidly evolving market. Now is the time to invest in AI, embrace the benefits, and prepare for a future where automation will be at the core of industrial success.

FAQs

1. What is industrial automation with AI?

Industrial automation with AI refers to the use of artificial intelligence technologies, such as machine learning and computer vision, to automate tasks in industrial environments. Unlike traditional automation, which relies on static rules, AI allows machines to learn from data and make intelligent decisions in real-time, leading to more efficient and flexible operations.

2. What industries benefit most from AI automation?

Industries that are heavily reliant on production and logistics, such as automotive, electronics, pharmaceuticals, and manufacturing, are among the biggest beneficiaries of AI automation. AI’s ability to streamline complex processes, improve quality control, and reduce downtime makes it ideal for industries where precision and efficiency are critical.

3. How does AI improve predictive maintenance?

AI enhances predictive maintenance by analysing data from sensors and equipment to predict when machinery is likely to fail. Instead of waiting for a breakdown, AI systems can alert operators to potential problems, allowing maintenance to be scheduled proactively. This minimises downtime, reduces repair costs, and extends the lifespan of equipment.

4. Will AI automation lead to job loss?

AI automation can displace jobs, particularly those involving repetitive or manual tasks. However, it also creates new opportunities, especially in areas like AI system development, maintenance, and oversight. Workers will need to adapt by learning new skills to manage and collaborate with AI technologies.

5. What are the key challenges of AI in industrial automation?

Key challenges include high implementation costs, data security and privacy concerns, technological complexity, and potential workforce displacement. Businesses must navigate these issues carefully to successfully integrate AI into their operations while ensuring that the benefits outweigh the risks.